Well, that can be debated, however a free copy of SpotOn! Flexo QM pressroom software is something you shouldn't pass up!

Especially when it will show you how to improve press-side color matching by simply Running to Delta E rather than using your old ink density standards.

Do you ever wonder why, in Flexo, we always target our Magenta ink density to 1.20 or Cyan to 1.30? Is that the best ink density to get the optimal color or is it just the target posted in the viewing booth near the press? Why do we use ink density to monitor color when it is a measurement of lightness or darkness?

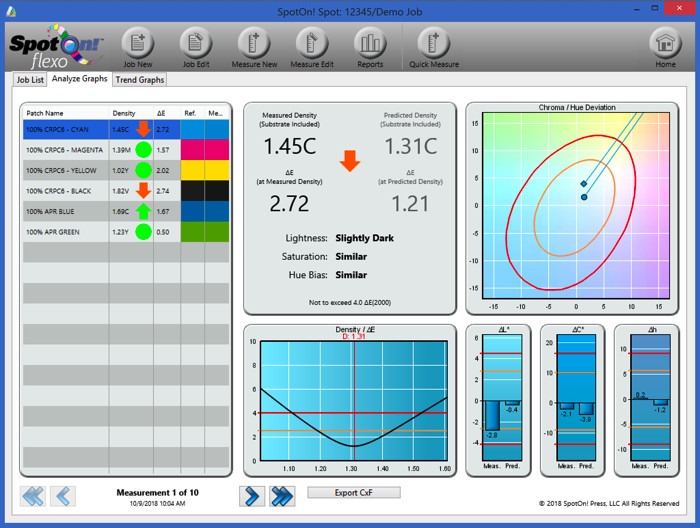

SpotOn! Flexo QM uses a Predictive Analysis Algorithm to provide press operators the optimal ink density to run a color to achieve the lowest Delta E (dE) color match to the desired reference color. This new pressroom metric is called Running to Delta E rather than running to solid ink density.

SpotOn! Flexo displays simple icons making it easy to understand and implement.

| Icon | Description |

|---|---|

| Acceptable Color Match - (based on dE to reference) |

| Acceptable Color Match can be achieved by Increasing or Decreasing solid ink density (SID) |

| Failed Color Match - (requires new ink formulation.) |